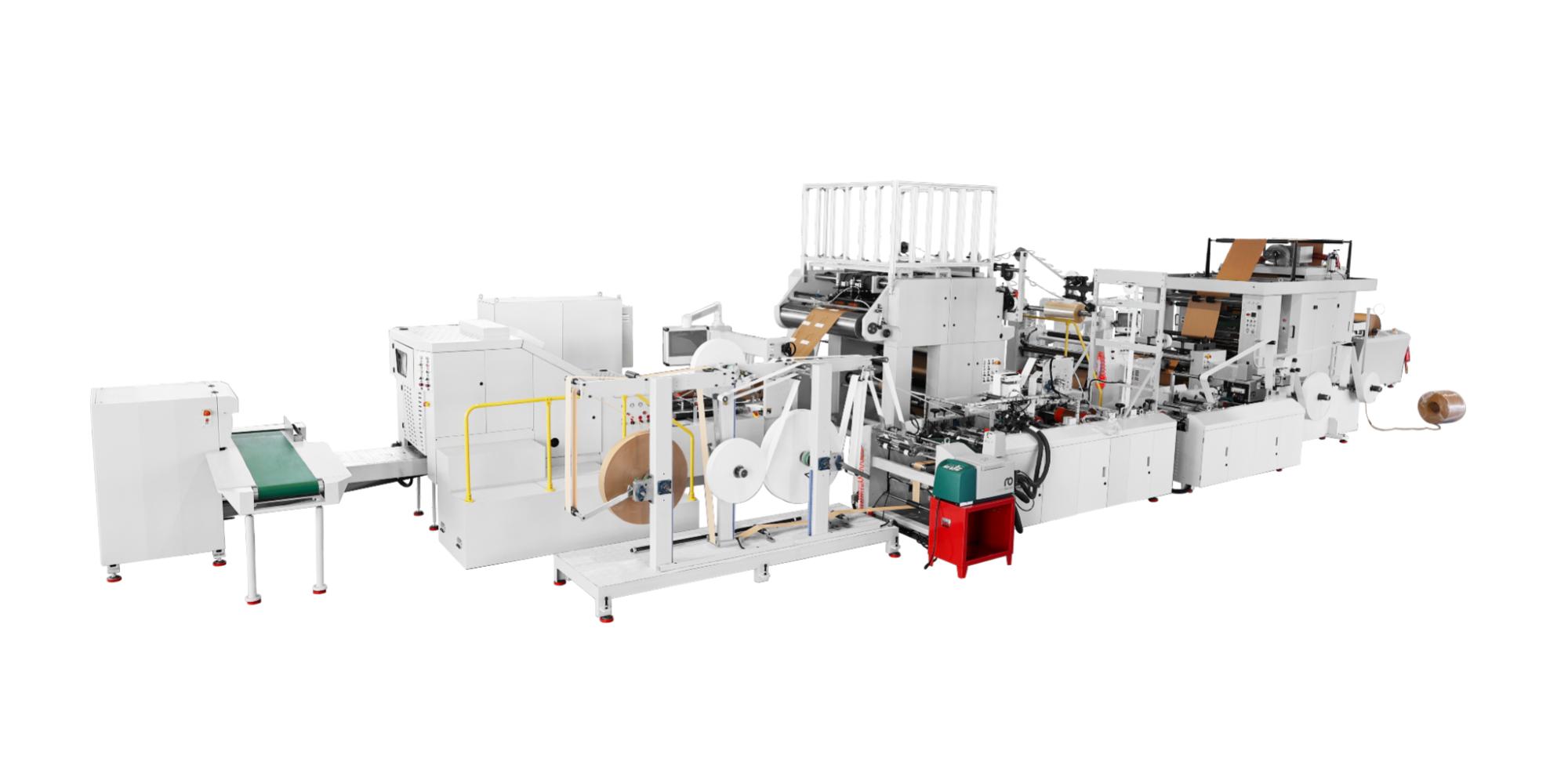

As the demand for eco-friendly packaging continues to rise, flat-bottom paper bags have become a popular choice in retail, food, and other sectors due to their excellent load-bearing capacity and appealing appearance. Our flat-bottom paper bag machine, designed with a modular concept, offers customers a stable and efficient paper bag production solution, helping businesses seize new market opportunities.

Precision Forming Technology for Consistent Quality

Equipped with original German LENZE servo motors and SICK photoelectric sensors, the machine ensures precise synchronization of paper feeding, creasing, and bag forming. Every bag produced features a firm, flat bottom with outstanding load capacity, effectively eliminating common issues such as bottom deformation or poor adhesion often found in traditional processes.

Versatile for a Range of Production Needs

Supports various paper types ranging from 80–150 g/m²

Capable of producing flat-bottom paper bags in different sizes (bag width 240–550 mm)

Smart and User-Friendly Operation

With a French SCHNEIDER touchscreen interface, all functions are intuitive and easy to manage. The optional automatic counting and stacking system significantly reduces manual sorting effort.

We provide comprehensive equipment commissioning and operator training services to ensure your production line is up and running quickly. Contact us for a detailed technical solution.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com