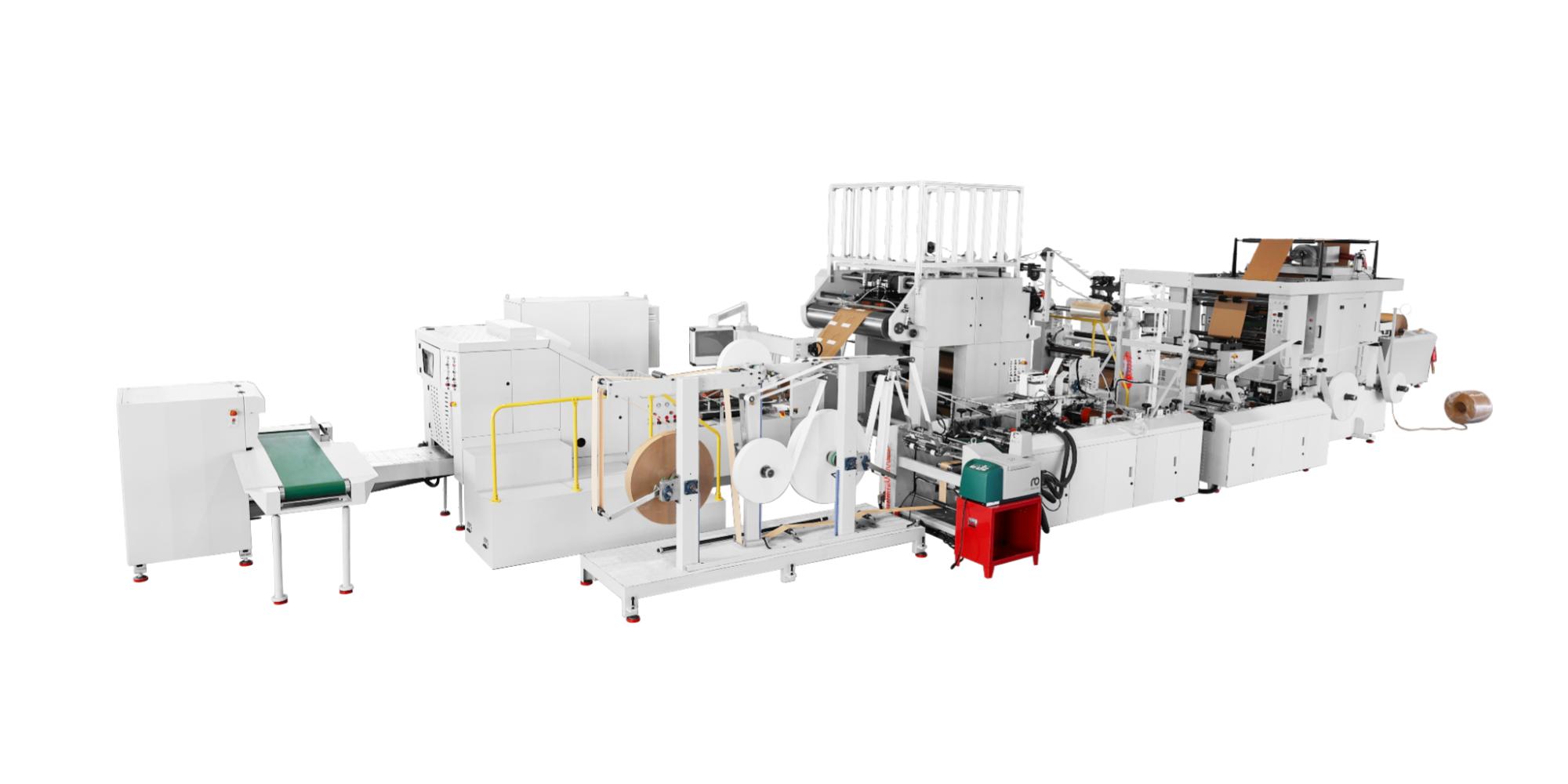

In the modern packaging industry, integrated production equipment has become the key to improving efficiency. The RZFD-550TF Round & Flat Handle Square Bottom Paper Bag Machine with Inline Printing combines bag forming and printing processes into one system, providing customers with a highly efficient and convenient production solution.

Integrated Design for Enhanced Productivity

This machine adopts an innovative integrated structure that seamlessly combines the paper bag forming and printing processes. From paper roll to finished handle bags, the entire production process is fully automated, reducing intermediate steps and significantly improving efficiency. The unique transmission system ensures precise synchronization of all processes, achieving production speeds of 30–110 bags per minute.

Versatile Production Capabilities to Meet Market Demand

Quick switching between round handle and flat handle bag types

Capable of producing handle bags with widths ranging from 240–550 mm

Printing unit supports multi-color continuous printing

Compatible with a wide range of paper materials from 80–150g/m²

Intelligent Control System for Stable Operation

A PLC control system paired with a touch-screen interface enables digital parameter setting and storage. The automatic web alignment system ensures accurate positioning of printed patterns. Real-time monitoring of machine status and automatic fault alarms further ensure smooth operation.

Typical Applications: supermarket shopping bags, branded promotional bags, and gift handle bags.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com