As a professional manufacturer of paper bag machinery, we have introduced the RZFD-190 square bottom paper bag machine with inline printing, whose core advantage lies in integrating both printing and bag making processes into a single workflow. This design completely eliminates the efficiency losses of the traditional “print first, then bag” production model, enabling packaging enterprises to build high-efficiency production lines for square bottom paper bags with superior appearance quality.

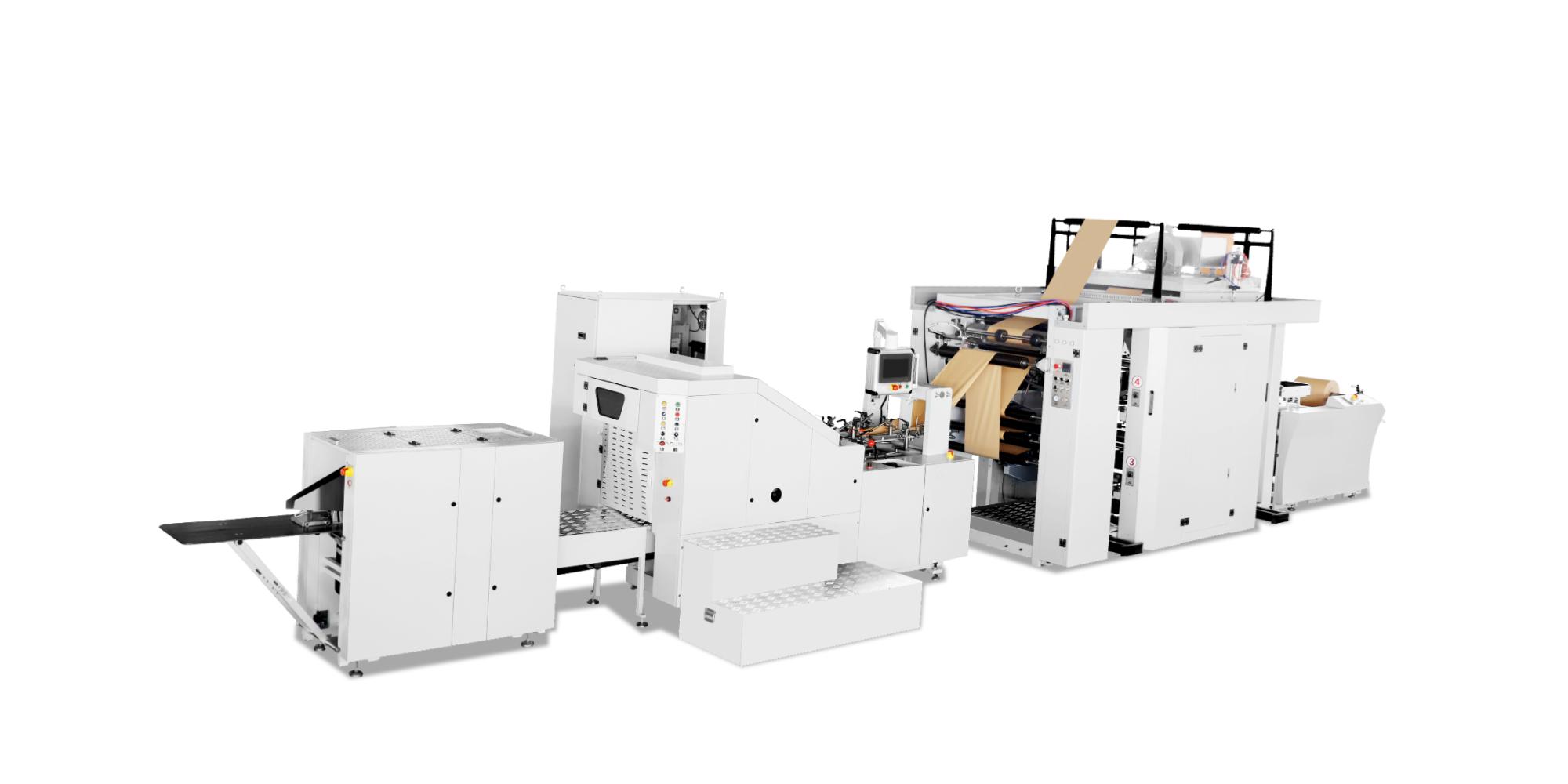

The equipment integrates roll paper unwinding, flexographic printing, creasing and forming, square bottom gluing, and finished bag output into one continuous process. It achieves full automation from raw material to finished product, without manual transfer or segmented operation, significantly shortening the production cycle and improving overall efficiency.

In terms of performance, the machine is equipped with a high-precision flexographic printing system that enables multi-color printing and accurate color registration. It can vividly reproduce brand logos, patterns, and text with sharp clarity, meeting the high standards of enterprises for packaging aesthetics and brand recognition. Combined with an intelligent feeding and positioning system, the bag forming process runs smoothly and precisely, ensuring consistent dimensions and well-shaped bags. The square bottom gluing section adopts constant-temperature control and automatic gluing technology, which ensures firm adhesion and a neat appearance, achieving both airtightness and visual appeal. This makes the machine ideal for producing packaging in industries such as food and daily chemicals.

The RZFD-190 supports various paper types and flexible switching between different bag sizes. Parameter adjustments are intuitive and fast, allowing the machine to adapt to diverse packaging designs and printing requirements. It is widely used for producing snack bags, bakery bags, shopping bags, and daily product packaging. By integrating printing and bag making, it not only reduces labor and material waste but also enhances the added value of brand packaging through customized printing designs—providing enterprises with an efficient, high-quality production solution that improves both output and brand presentation.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com