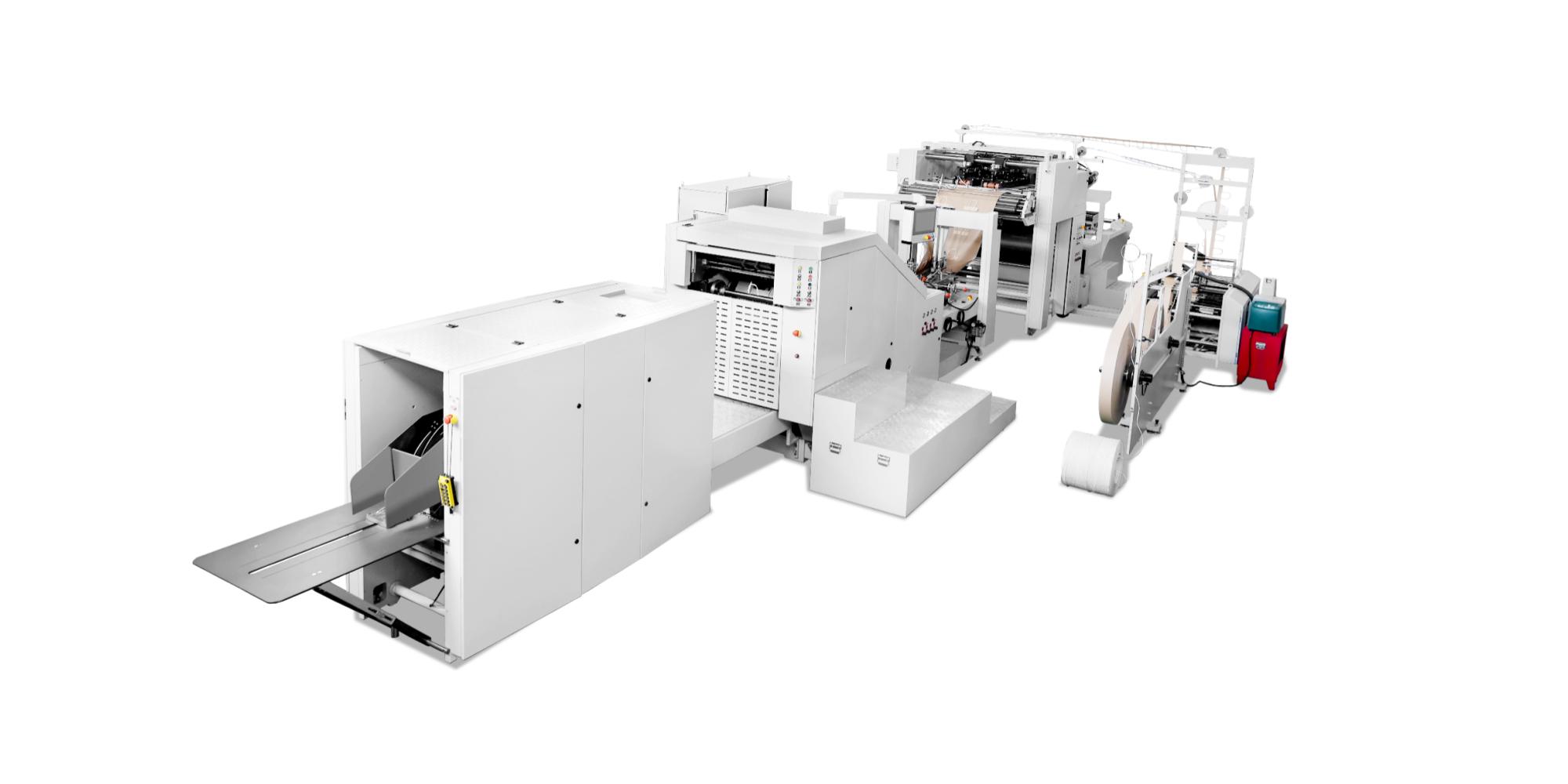

The RZFD-250T round rope handle square bottom paper bag machine is developed under the core concept of “user-friendly operation and versatile application.” By integrating the round rope handle making and square bottom paper bag forming processes, it offers an efficient, intelligent, and flexible production solution for small and medium-sized packaging enterprises. The equipment has been systematically optimized in operation experience, maintenance convenience, and material adaptability, helping enterprises achieve higher productivity and superior packaging quality within limited production space.

In terms of intelligent operation, the machine is equipped with an intuitive touch control system where key production parameters—such as bag making speed, gluing temperature, and bag dimensions—can be visualized, set, and monitored in real time. The system supports storage and quick recall of multiple production recipes, enabling order changeovers without repeated adjustments and greatly shortening production switching time. The built-in intelligent diagnostic module continuously monitors the running status of rope threading, paper feeding, and temperature control systems. In case of any abnormality, the machine automatically stops and displays the fault location, accompanied by sound and light alarms, allowing operators to quickly identify and resolve issues to ensure continuous and efficient production.

The equipment adopts a modular design where the rope threading and bag making units are independent and easy to maintain. Common wearing parts can be replaced without dismantling the entire machine, making daily maintenance faster and more efficient. The optimized transmission system operates smoothly with low mechanical noise, and the overall structure is solid and reliable, providing a more comfortable working environment and longer service life.

In terms of application, the RZFD-250T demonstrates excellent adaptability across industries. In food packaging, it enables precise printing of brand information and nutritional details; in cultural and retail packaging, customized handle colors and printing schemes allow for differentiated packaging designs. The machine also supports the use of various eco-friendly paper materials, helping enterprises implement green manufacturing practices and align with the global trend of plastic reduction.

The RZFD-250T round rope handle square bottom paper bag machine deeply integrates the handle forming and bag making processes, achieving efficient coordination from material feeding to finished bag output. With precise tension and photoelectric positioning systems, every bag is formed stably with consistently aligned handle positions. An optional remote monitoring module allows users to view production data, operating status, and energy consumption information in real time via mobile devices, enabling digital management and remote maintenance of the production process.

With its intelligent control system, flexible adaptability, and reliable performance, the RZFD-250T has been widely adopted by numerous packaging manufacturers. It helps customers improve production efficiency, optimize labor input, and gain a competitive edge in the customized packaging market. Whether for consumer goods companies focusing on brand image or manufacturing plants seeking efficient management, this machine delivers high performance and flexibility, serving as a powerful driver for upgrading modern packaging production.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com.