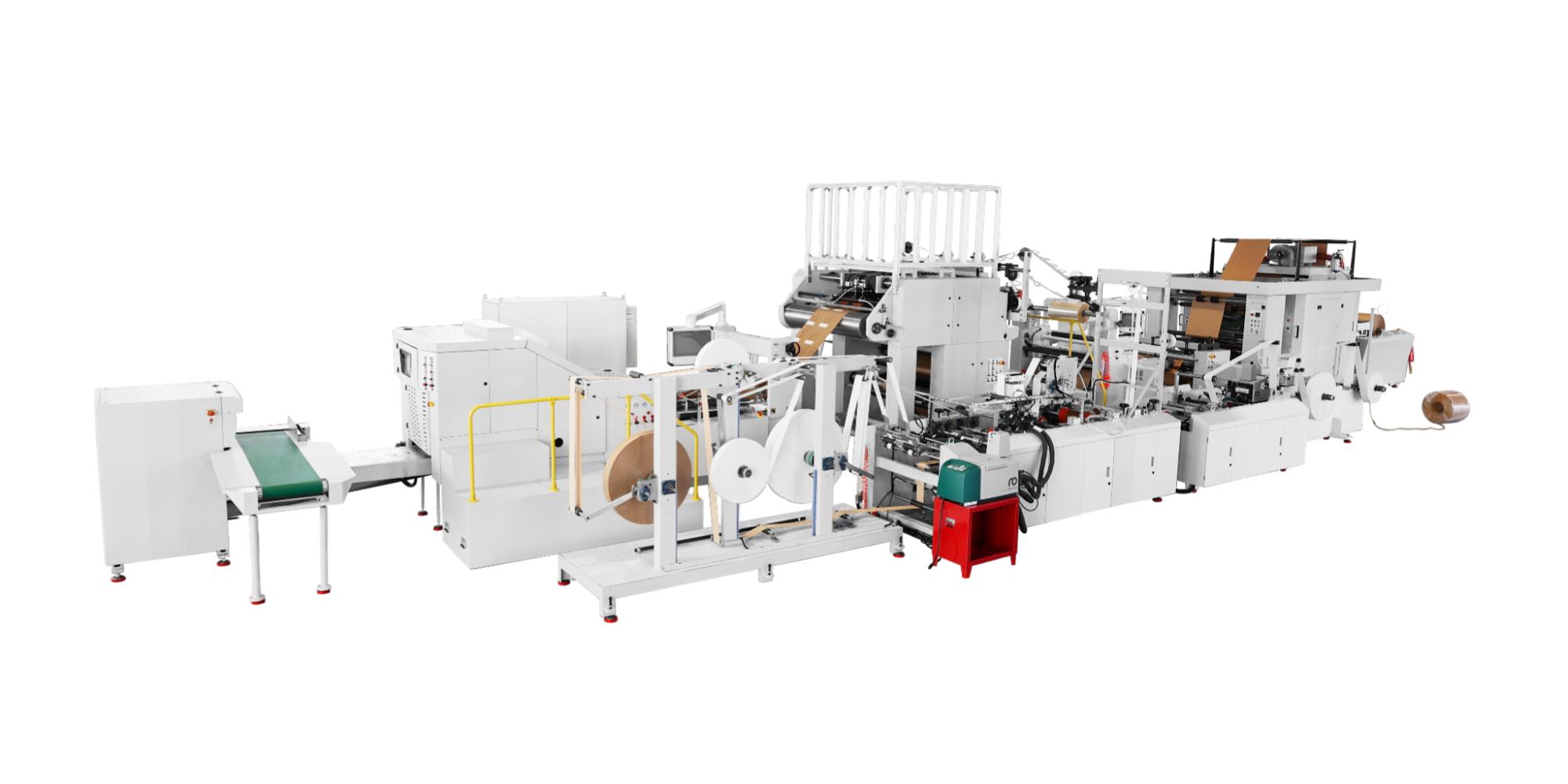

The RZFD-450ATF round and flat handle integrated square bottom paper bag machine, independently developed by our company, is designed with the technical core of “user-friendly operation and versatile application.” It comprehensively optimizes three key aspects—human–machine interaction, maintenance convenience, and material compatibility—providing small and medium-sized packaging enterprises with an efficient solution for intelligent and customized production upgrades.

In terms of operation experience, the machine is equipped with a large Schneider color touch screen. Key process parameters such as handle type, bag making speed, heating temperature, and bag length can be easily set and adjusted with visualized control. Multiple sets of frequently used production recipes can be stored and quickly recalled, allowing seamless order changes without repeated adjustments and significantly reducing setup time. The built-in fault diagnostic system monitors production status in real time; when an abnormality occurs, the machine automatically stops and displays error information, accompanied by sound and light alarms. This helps operators quickly identify and resolve issues, ensuring safe and continuous production.

From a maintenance perspective, the equipment continues the modular design concept, with independent handle and bag making units. Key components are designed for quick disassembly and replacement, facilitating daily maintenance and minimizing downtime. The main transmission system is precisely matched and dynamically balanced for smooth, low-noise operation, providing operators with a more comfortable working environment.

Designed for diverse application scenarios, the RZFD-450ATF offers excellent adaptability across industries. In food packaging, it supports the production of printed flour bags, snack bags, and other handled packages, with all contact components meeting food-grade hygiene standards. In the cultural and creative packaging sector, customizable handle colors enable large-scale production of branded gift bags. The equipment fully supports a wide range of eco-friendly paper materials, including biodegradable kraft paper and recycled white card paper, helping enterprises achieve green manufacturing transformation.

With its integrated handle forming and bag making structure, the RZFD-450ATF delivers outstanding flexibility while maintaining high production efficiency. It easily accommodates multi-batch and small-lot production tasks, reducing inventory and changeover costs. The tension control system automatically adapts to different paper weights, while the photoelectric positioning system ensures precise alignment between handles and bag bodies, guaranteeing stable product quality. The machine also reserves an interface for remote monitoring functionality, allowing real-time viewing of production status, energy consumption, and maintenance data via mobile devices to support digital management and decision-making.

With its intelligent, user-oriented design and stable operational performance, the RZFD-450ATF round and flat handle integrated square bottom paper bag machine has been widely adopted by packaging enterprises, demonstrating excellent reliability and adaptability. Whether for customized brand clients emphasizing image and quality, or OEM manufacturers focused on high-efficiency production, this machine provides powerful support with its flexibility, efficiency, and stability—helping enterprises achieve high-quality packaging production and enhanced competitiveness.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com