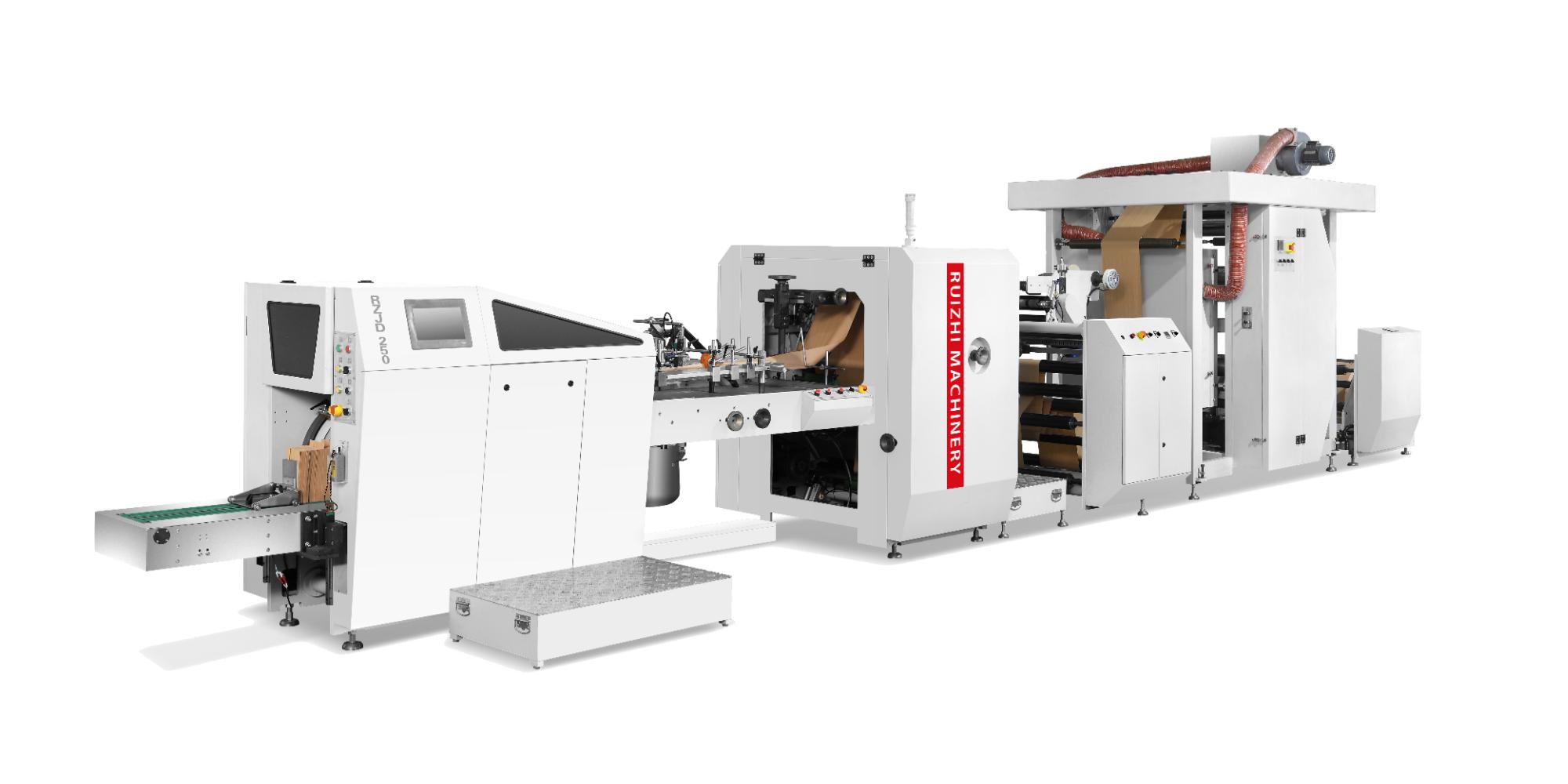

The G250J flat bottom paper bag machine with printing inline, independently developed by our company, is designed around the core concepts of “easy operation, simple maintenance, and strong adaptability.” It optimizes the user experience across multiple dimensions including human–machine interaction, maintenance efficiency, and material compatibility, making it an ideal choice for small and medium-sized packaging enterprises seeking intelligent and customized flat bottom bag production upgrades.

In terms of intelligent operation, the machine is equipped with a Schneider color touch screen, allowing intuitive setting and real-time monitoring of key parameters such as printing color scale, registration precision, bag-making speed, and bag length. The system supports multi-recipe storage and one-touch recall, enabling quick order changeovers without repeated adjustments and significantly improving production efficiency. New operators can become proficient after brief training. The built-in intelligent fault diagnosis system continuously monitors the operating status—such as ink supply interruption, paper deviation, or temperature control anomalies—and automatically stops the machine when an abnormality occurs. The system also triggers an audible and visual alarm, helping operators quickly locate and resolve issues to ensure production continuity and safety.

The equipment adopts a modular structural design, with independent printing and bag-making units for easy maintenance and disassembly. Common wearing parts such as paper feeding rollers and gluing components can be replaced quickly without dismantling the entire machine, making maintenance simple and efficient while significantly reducing downtime. The core transmission system is precisely calibrated to ensure stable operation and low noise, complying with industrial noise control standards and creating a comfortable working environment for operators.

In application scenarios, the G250J demonstrates exceptional compatibility. In the food packaging sector, it can produce printed paper bags for nuts and bread; in agriculture, it can manufacture moisture-proof and leak-resistant seed bags; and for dry goods and retail packaging, it flexibly accommodates various paper weights and surface finishes. The machine also supports multiple eco-friendly paper materials, such as biodegradable kraft paper, helping enterprises actively practice green and sustainable development.

With its efficient integration of printing and bag-making processes, user-friendly operation and maintenance experience, and wide industry adaptability, the G250J flat bottom paper bag machine with printing inline has been successfully applied in numerous packaging enterprises. It helps customers effectively reduce production and management costs, enhance packaging quality and brand value, and deliver more efficient and competitive packaging solutions for their businesses.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com