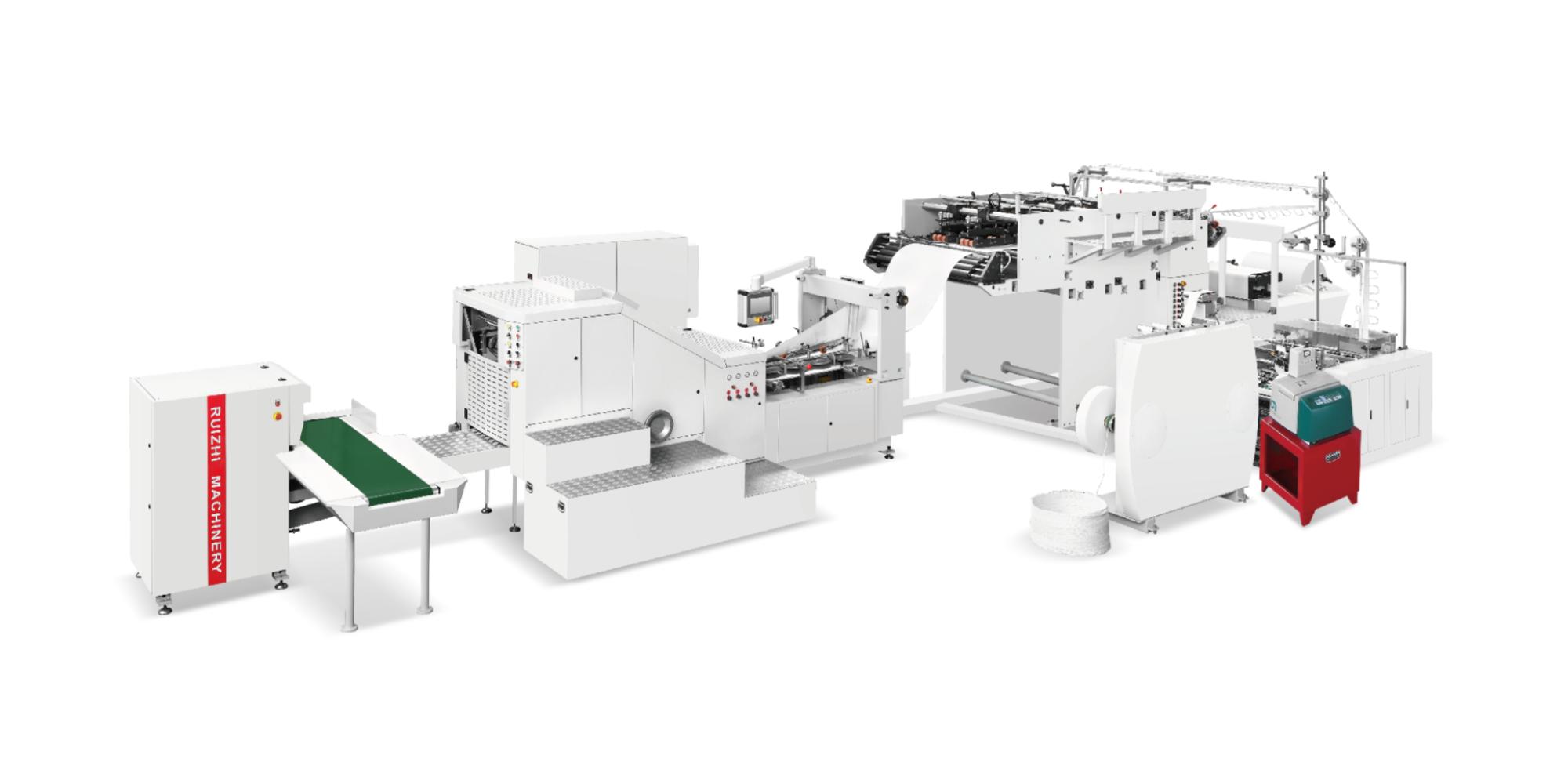

The RZFD-330T square bottom paper bag machine with twisted handle inline was designed from the outset around practical production requirements such as user-friendly operation, simplified maintenance, and strong adaptability. From human–machine interaction, daily maintenance efficiency, to usage scenarios across different industries, this model has undergone systematic optimization of the overall operating experience. It is well suited for small and medium-sized packaging enterprises seeking stable expansion of handled paper bag production and improved efficiency based on their existing production foundations.

At the operation level, the machine is equipped with an intuitive touch-screen interface. Common process parameters can be centrally managed and called according to production needs, eliminating the need for repeated fine adjustments during order changeovers and helping to shorten preparation time. The system logic is clear, allowing newly trained operators to carry out independent operation after brief training. During operation, the control system continuously monitors handle threading status, paper feeding conditions, and temperature control status. When abnormalities occur, the machine automatically enters a protective state and provides interface prompts to assist in rapid problem identification, thereby reducing the impact of unplanned downtime on production rhythm.

In terms of application adaptability, the machine allows flexible adjustment of production configurations according to the packaging requirements of different industries. In food packaging applications, it can meet requirements for bag sealing performance and material safety. In daily chemical and cultural and creative product applications, it demonstrates good adaptability to paper surface treatments and handle rope combinations, helping enhance overall packaging texture. In supermarket and daily consumer use scenarios, it can stably produce paper bags suitable for routine handling needs. At the same time, this model is compatible with a variety of paper materials and can work with environmentally friendly paper options, supporting enterprises in balancing functional requirements with sustainable development goals during production.

With its stable coordination between handle threading and bag forming, relatively simplified operation and maintenance methods, and strong application flexibility, this model has been put into practical production use by many small and medium-sized packaging enterprises. It helps users improve product consistency and delivery stability while controlling production costs, enabling them to better respond to diversified market demands.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com