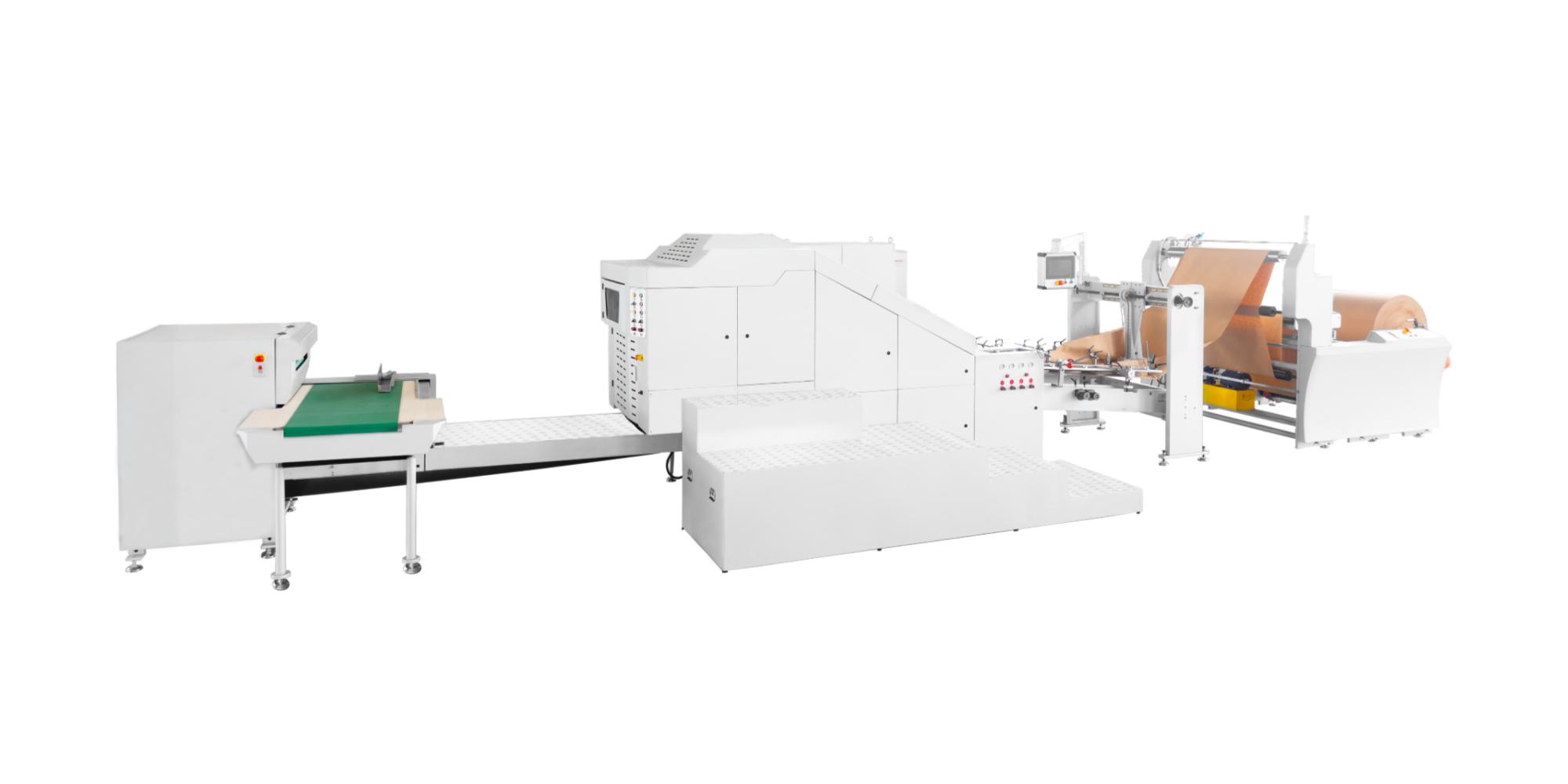

The RZFD-450A square bottom paper bag machine is developed with optimization focused on the practical production requirements of kraft paper packaging. Through systematic integration of operation methods, maintenance procedures, and application adaptability, the machine maintains stable operation while better meeting the needs of small and medium-sized packaging enterprises for eco-friendly and scaled production. It is suitable for building square bottom paper bag production lines designed for long-term, sustainable operation.

At the operation and control level, the machine adopts a touch-screen interface. Bag-making rhythm, bag size specifications, and gluing-related settings can be centrally managed and visually displayed, while commonly used process parameters can be stored and recalled according to order requirements, helping shorten changeover preparation time. The overall operating logic is clear, allowing new operators to participate in normal production after completing basic training. During operation, the control system continuously monitors paper feeding status, temperature control conditions, and material supply status. When abnormalities occur, the machine automatically enters a protective state and provides interface prompts to assist in rapid problem identification, reducing the impact of troubleshooting on the production rhythm.

In terms of structural and maintenance design, the machine applies a modular approach to high-frequency maintenance areas. Cutting and gluing-related components can be independently disassembled and assembled, allowing routine replacement and inspection without complex disassembly of the entire machine. This makes maintenance procedures more direct and efficient. The transmission system is finely adjusted during assembly, ensuring stable operation, while noise levels are controlled within a reasonable range for industrial production environments, helping improve long-term operating conditions at the production site.

Regarding application adaptability, the machine allows flexible adjustment of production configurations according to packaging requirements across different industries. In food packaging applications, it meets basic requirements for moisture resistance and bag structure stability. In supermarket and daily consumer goods sectors, it is suitable for continuous production of shopping bags that are convenient for carrying and use. At the same time, the machine demonstrates good compatibility with various eco-friendly kraft paper materials, enabling enterprises to adjust production in line with green material application needs.

With stable operating performance, relatively simplified operation and maintenance processes, and strong application flexibility, the RZFD-450A square bottom paper bag machine has been put into practical use by many small and medium-sized packaging enterprises. It helps users improve product consistency and market adaptability while controlling production costs.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com