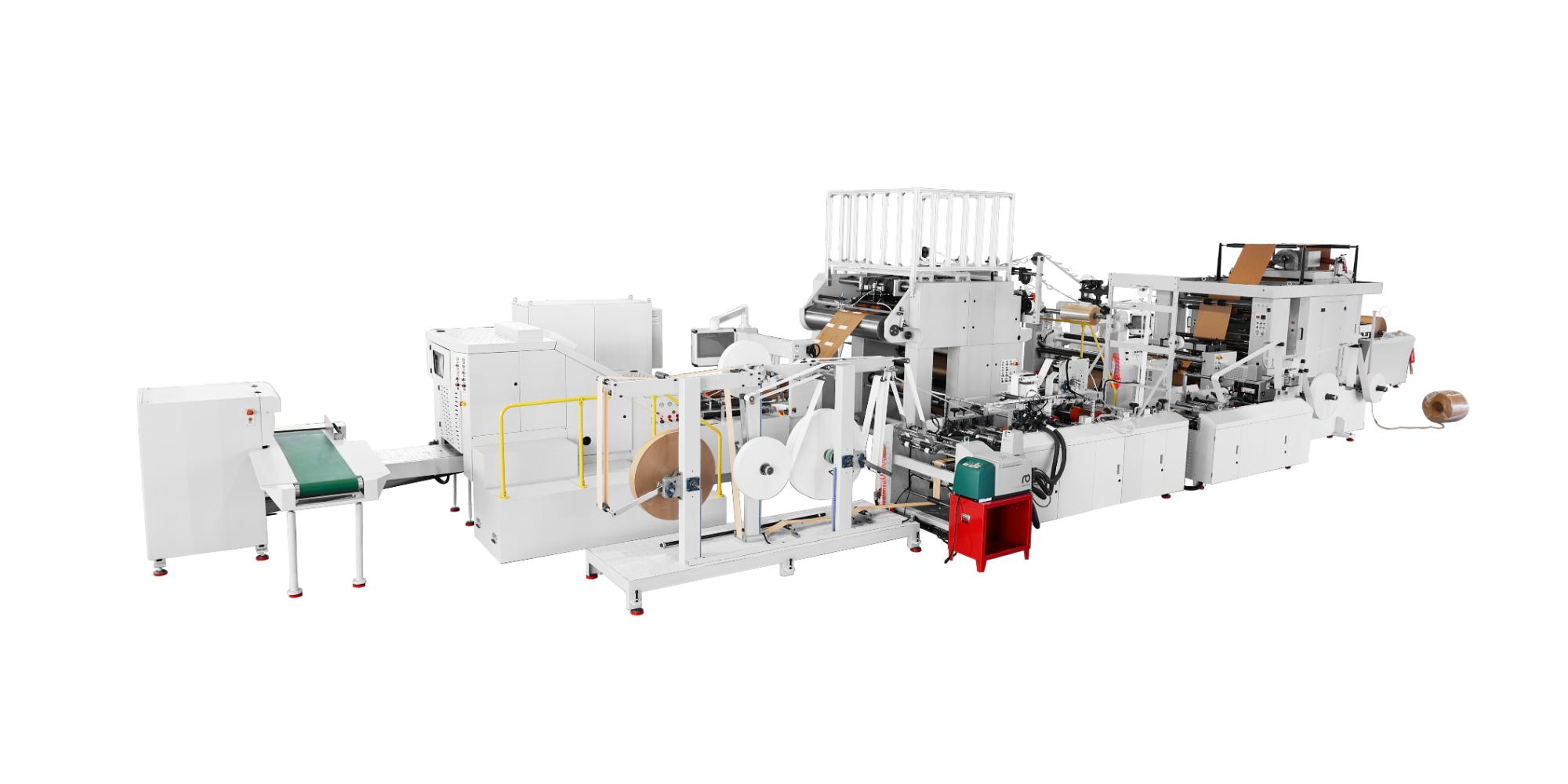

The RZFD-550TF paper bag machine with twisted and flat handle inline, independently developed by our company, is designed with the technical focus on “easy operation and versatile application.” It optimizes the user experience across multiple dimensions including human–machine interaction, maintenance efficiency, and material adaptability, making it an ideal solution for small and medium-sized packaging enterprises to achieve customized and intelligent production upgrades.

The equipment adopts a modular design, with independent configurations for the handle unit and bag-making mechanism, ensuring convenient maintenance and replacement. Common wearing parts such as rope feeding wheels and gluing components can be quickly removed, minimizing downtime and maintenance costs. The core transmission system is precisely calibrated to ensure smooth and quiet operation with excellent noise control, providing operators with a more comfortable working environment.

In terms of application, the RZFD-550TF demonstrates outstanding adaptability across industries. In the food and catering packaging sector, it can produce various types of eco-friendly paper bags such as bakery bags, beverage takeaway bags, and snack bags. In the retail and apparel industries, it enables efficient mass production of branded shopping bags and gift bags. In the cultural and premium packaging sectors, customized handle colors and printing solutions can be applied to create distinctive visual effects. The machine also supports the use of various eco-friendly materials, such as biodegradable kraft paper and recycled white card paper, helping enterprises transition toward sustainable packaging solutions.

With its integrated structure combining handle forming and bag making, the RZFD-550TF flexibly accommodates multi-size, small-batch, and diversified order requirements. It helps enterprises increase production line switching speed, reduce inventory pressure, and lower labor costs. The intelligent tension control system automatically adjusts operation parameters based on different paper properties, while the photoelectric positioning system ensures precise handle placement and consistent bag structure. An optional remote monitoring module allows real-time viewing of production data—including output, energy consumption, and operating status—via mobile devices, supporting digital management for enterprises.

Through its intelligent and flexible production mode, the RZFD-550TF paper bag machine with twisted and flat handle inline has been successfully applied in numerous packaging enterprises. With its stable performance and excellent adaptability, it helps customers enhance production efficiency and strengthen brand competitiveness. Whether for brand owners pursuing packaging personalization or manufacturers focusing on refined production, this machine delivers high efficiency, flexibility, and reliability, providing sustained momentum for the upgrading of the packaging industry.

About Ruizhi Machinery

Ruizhi Machinery leads the way in eco-friendly packaging solutions, committed to a sustainable and innovative future. With over 20 years of expertise, our paper bag machines are recognized globally for their unmatched efficiency and reliability. Trusted by customers in over 120 countries across Europe, America, Asia, and Africa, our products set the standard for quality and performance. For more information about Ruizhi Machinery, please visit www.mted.com or www.wzruizhi.com